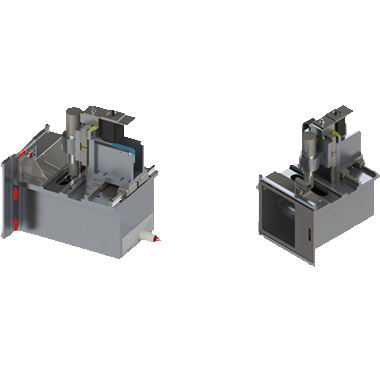

The Glorious GZ5 is a five-axis five-link dental milling machine, primarily used for cutting zirconia materials. This device features a compact structure and powerful functionality, capable of cutting various types of dentures to meet the personalized needs of customers.

GZ5 Dental Milling Machine

5 Axis 5 Linkage Zirconia Milling Machine · CAD CAM Milling Machine · Dental Lab Milling Machine

Product Introduction

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

The Glorious GZ5 is a five-axis five-link dental milling machine, primarily used for cutting zirconia materials. This device features a compact structure and powerful functionality, capable of cutting various types of dentures to meet the personalized needs of customers.

Advantage

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Comprehensive Alarm System

This device is equipped with a comprehensive alarm system that provides warnings during operation and alerts users to actions that may cause damage to materials, tools, or machines, such as:

A) Low air cooling pressure

B) Insufficient air pressure during tool replacement

C) Tool retrieval failure or unsuccessful tool return

D) Automatic tool calibration when wear on the tool path exceeds 0.05mm

E) Tool breakage during cutting

F) Forcing the spindle not to clamp the tool before program execution when the tool number is incorrect; after processing is complete, the tool is returned to the tool library to prevent the user from placing the wrong tool.

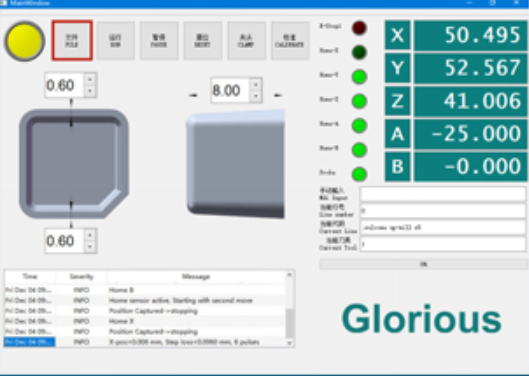

Friendly Human-Computer Interface

The equipment comes with a touchable operation panel and WIFI built in,which can be remotely controlled, and convenient for training,diagnosis and maintain

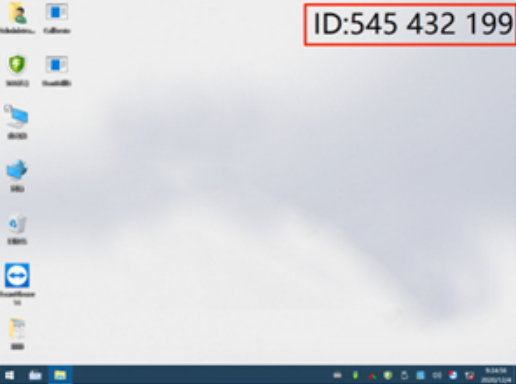

Each equipment has an independent ID.When the equipment has a problem, the manufacturer can perform remote diagnosis and maintenance based on the ID; these can reduce the issue solving time.

Open CAM System

The equipment is compatible with any CAM system on the market, such as: WorkNC、Millbox,Sum3D,Hyperdent, etc.

Automatic Calibration and Automatic Processing

The equipment has an automatic calibration function, which ensures the accuracy of the equipment and avoids errors when it begins to formal cut. These can save time and materials.

Various Fixture Modes

The equipment fixture can be adjusted to a material-saving mode, and a large-size plate material (such as CERCON) can also be installed.

Excellent Cleaning Effect

The equipment has a good dust suction effect, and there is an air duct in the working chamber to avoid vacuuming during processing, causing dust to be unable to be completely sucked out.

Long-Term Maintenance Accuracy and Longer Service Life

The equipment is a box structure, each axis has 4 sliders, with high rigidity, which can ensure that the body is not deformed during use or transportation, maintain the accuracy of the equipment for a long time, and make the life of the machine longer.

Equipment Parameters

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

| Model | GZ5 |

| Volume | 470*393*475mm |

| Axis Quantity | 5-axis and 5-linkages |

| Motor | Micro Step Servo |

| Spindle | 500W+ATC |

| Spindle Cool | Air Cool |

| Workpiece Cool | Dust Clean |

| Tool Library | 6 |

| Tool Size | R1*L18mm/R0.5 *L16mm/R0.3*L10mm |

| Power | 1.0KW |

| Weight | 75KG |

| Positioning Accuracy | 0.005mm |

| Repeat Positioning Accuracy | 0.008mm |

| Maximum Speed | 3600mm/min |

| A-axis Rotation Angle | (-25)~(25) |

| B-axis Rotation Angle | 0~(360) |

| Machinable Material Size | Φ98*10~25mm/CERCONΦ105*10~25mm |

| Machinable Material | Zirconia/Wax/PMMA |

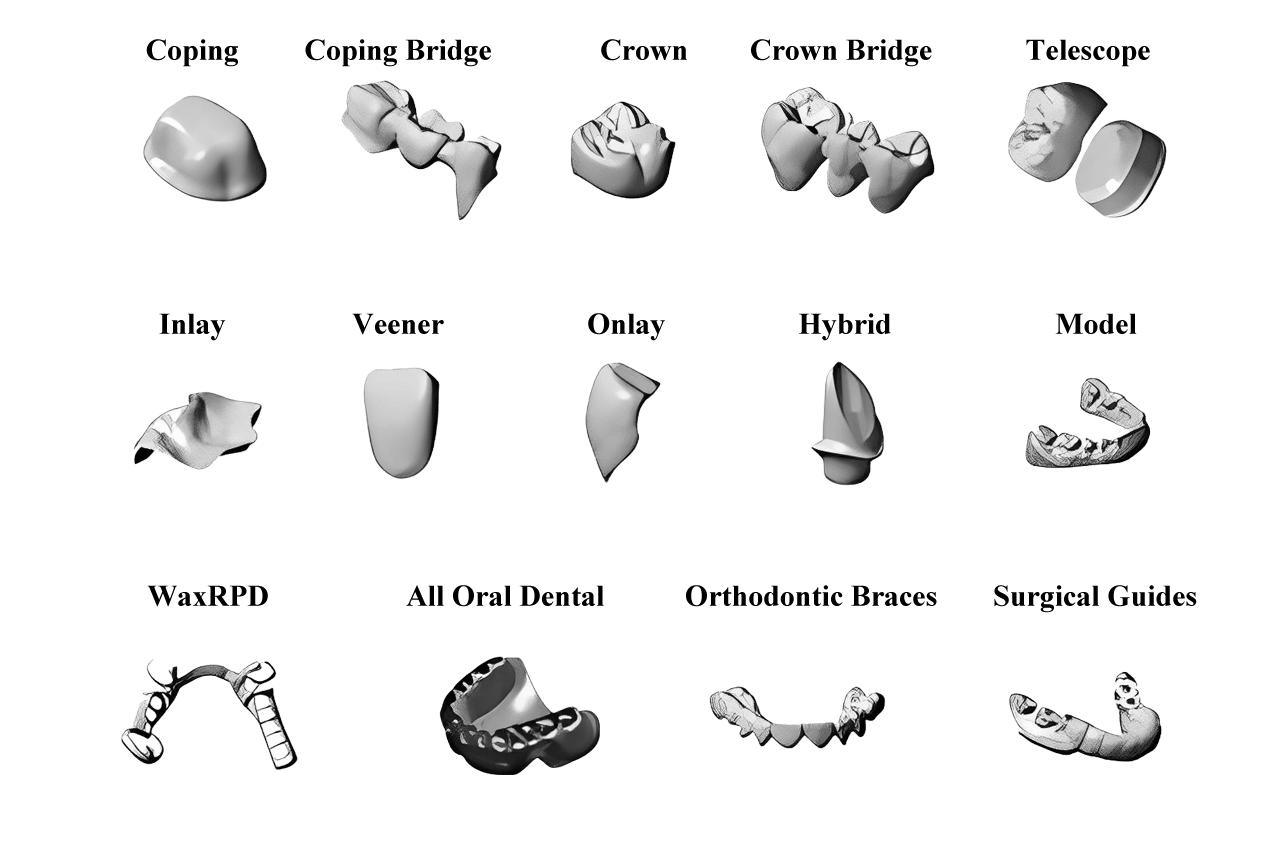

Machinable Products

*The total length of the tool is 45mm,L means blade length

Send a Message