Paste Glaze/Stain

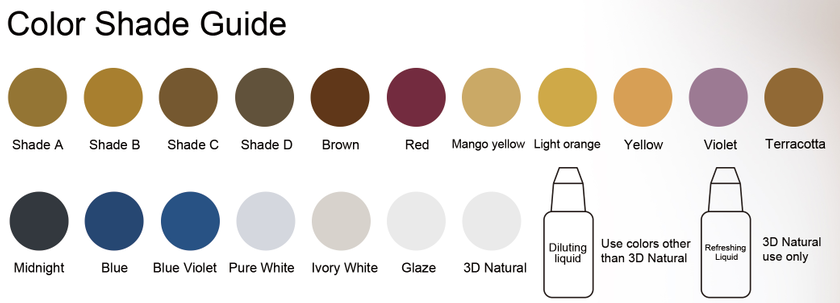

Available in 18Shades for post-sintered characterization

lt is suitable for the glazing of all types of dental ceramic restoration materials such as zirconia and glass ceramics.

The Stain & Glaze Paste set includes four main ABCD shades, 18 special effect colors, glaze, 3D natural shade, diluting and refreshing liquid. Each bottle of paste contains glaze ingredients. There is no need to apply glaze separately.The ideal effect can be achieved by stain only once. Glaze paste, fine particles, no need to mix powder and liquid before use. In order to achieve a satisfactory effect on the shade of the crown, theshades of each paste can be matched at will, and can be used directly after mixing evenly.

First Sintering | Second Sintering | Single crown transparent glaze sintering | Zirconia long bridge sintering (4-7 units) | Zirconia long bridge sintering (8 units and above) | |

| Starting temperature (°C) | 450 | 450 | 450 | 450 | 450 |

| Drying time (minutes) | 5 | 5 | 3 | 5 | 5 |

| Heating rate (°C/min) | 50 | 50 | 50 | 50 | 50 |

| Vacuum starting temperature (°C) | 500 | 500 | 500 | 500 | 500 |

| Vacuum end temperature (°C) | 780 | 780 | 780 | 780 | 780 |

| Sintering temperature(°C) | 780 | 780 | 780 | 780 | 780 |

| Keeping time (minutes) | 3 | 3 | 3 | 3 | 3 |

| Cool slowly (minutes) | 5 | 5 | 5 | 5 | 5 |

| Out of oven temperature(°C) | 500 | 500 | 500 | 500 | 500 |

1.Since the sintering furnaces of customers are different, if it is found that the sintering is not translucent enough, the sintering temperature can be increased or the holding time can be extended to improve the sintering quality.

2. If cracks are found in the zirconia denture itself after sintering is completed, the cooling time can be extended or the zirconia denture can be baked at a lower temperature to avoid micro-stress cracks in the zirconia caused by rapid cooling.

3. If the sintering furnace cannot be evacuated, increase the final sintering temperature (it is recommended to increase it by 20-50°C).

Full Zircon,Copings,PFM,Glass ceramic

Store in dry conditions, optimal temperature 12C-38℃.

After use, tighten the bottle cap and place it in a hygienic environment.

1. Please do not pour out the excess glaze liquid in the paste bottle.

2. Please mix the paste and liquid evenly before daily use to ensure the consistency and operational feel of the paste during use.

3. Each bottle of paste contains glaze ingredients, so there is no need to apply glaze separately.

4. Please make sure to use a clean and dry glaze brush and do not mix water into the paste. lf water is mixed into the paste, white mist particles will be produced after sintering.

5. During the paste preparation process, add an appropriate amount of diluent and mix thoroughly in a clockwise direction to ensure that there are no bubbles in the paste.

6. Please use steam or ultrasonic oscillation cleaning machine to clean the surface before stain & glaze.

Send a Message