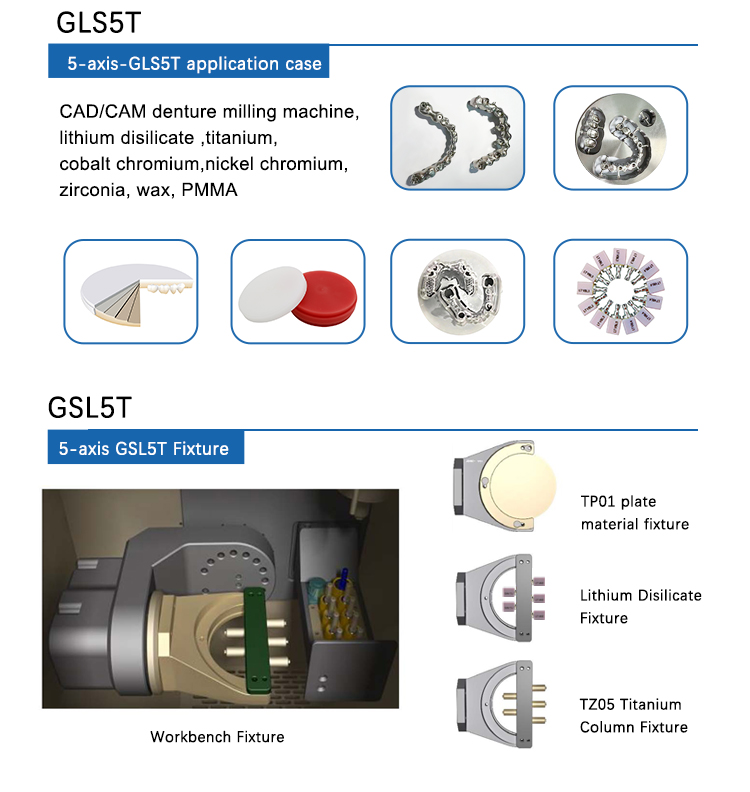

GSL5T, which is a new 5 axis dental machine end product and a cutting machine that can cut dental materials such as titanium and premill blocks. If you are interested in dental materials, you may wish to continue to listen to understand.

GSL5T is a wet five-axis milling machine. It is the most cost-effective milling machine for cutting and planting bars and planting abutments.So, when it comes to professionalism that everyone cares about, how to make one implant abutments?We ask Rebecca to explain it.

Scan the STL model data obtained in the patient's mouth with a intraoral scanner and import it into our design software (3Shape or Exocad) ,Match the scan boby to the corresponding implant data model, carry out the design, and export the STL file after the design ,then adjustment of the abutment angle during the design process.

Considerations when designing abutments:Reserve space under the gums. The position of the sleeve refers to the gingival curvature of the adjacent teeth, the opening situation is followed up with the judgment of the occlusal situation, the occlusal space is reserved, and the convergence angle is adjusted

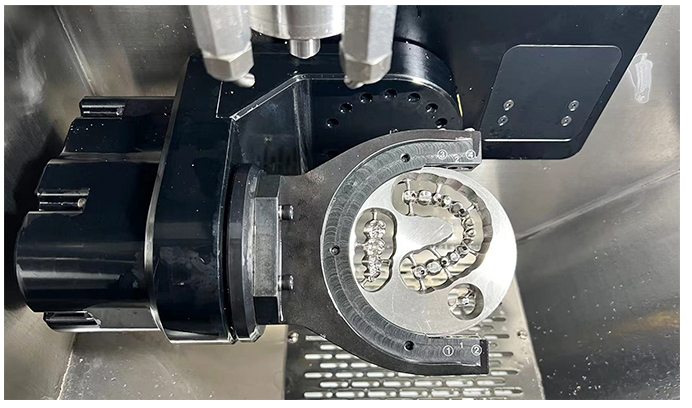

After the design is completed, import it into the typesetting software (hyperdent. Select the corresponding titanium column machine for typesetting. After the calculation is completed, generate NC data and import it into the engraving machine for cutting

Our machine include CAM software Hyperdent.

GSL5T model with 9 milling burs, it is automatic tool change technology.When make tool change, the magazine automatically pop up, not used when recovered, more convenient hygiene.China ' s best spindle, 1.8KW high power, 60000rpm, relative to air cooling is more suitable for dental machines. And the spindle has throttle valve, can be in 1s. water cooling, protect the needle, prolong life.

As far as I understand ,The machine needs to maintain good stability to mill implant case, and our machine adopts international hamina technology, has a solid body to ensure that processing less shaking. And there is a double-layer filter at the bottom to speed up the water cycle and ensure a cleaner coolant for the spindle.

For wet milling, It is good for titaium block ,COCR, lithium disilicate ,Titaium column, it mainly make implant bars and implant abutments.