Workbench

High dust collection, super quiet and comfortable working environment

Workbench

High dust collection, super quiet and comfortable working environment

Distribution of processing sectors

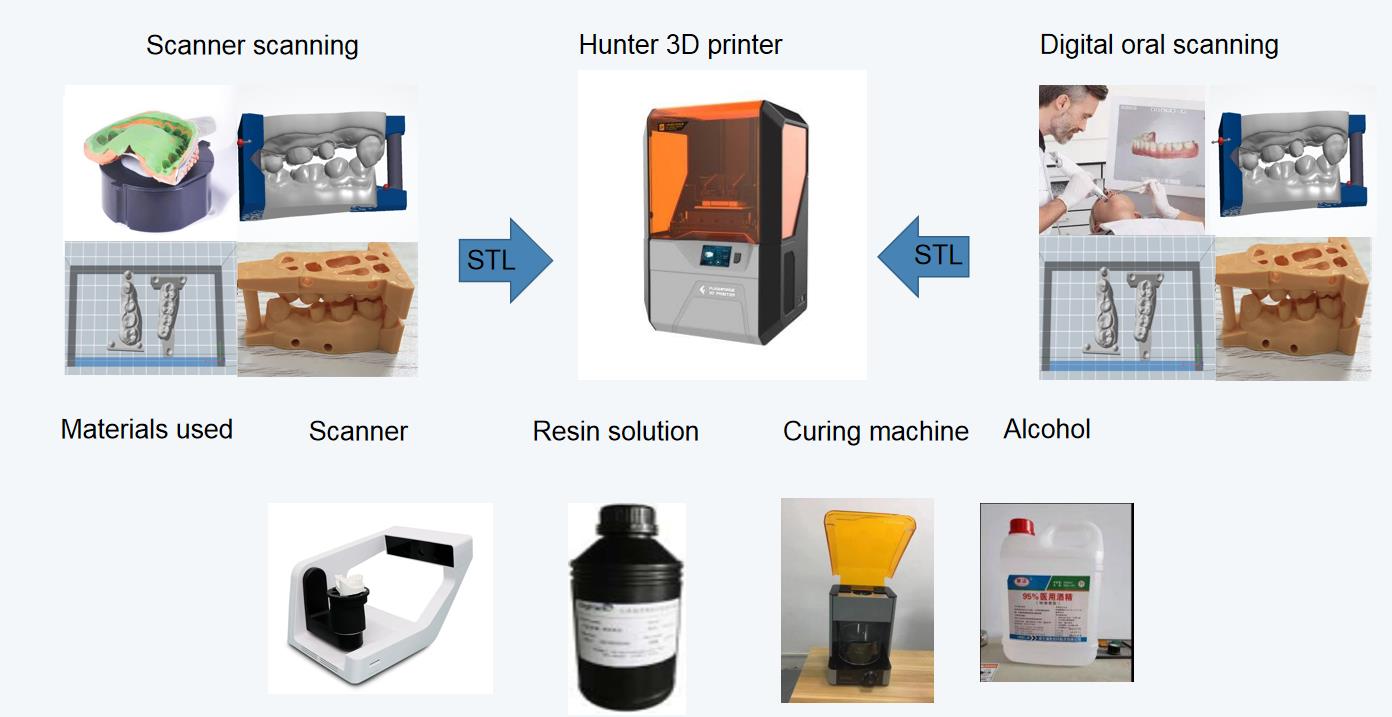

1. Model group

Digital scanning model

Traditional model selection

Shortcoming: Taking impression in the mouth is easy to cause discomfort and nausea. Silicone rubber is easy to deform, resulting in inaccurate model, waste of resources and poor environment

Tools required for manual mold removal

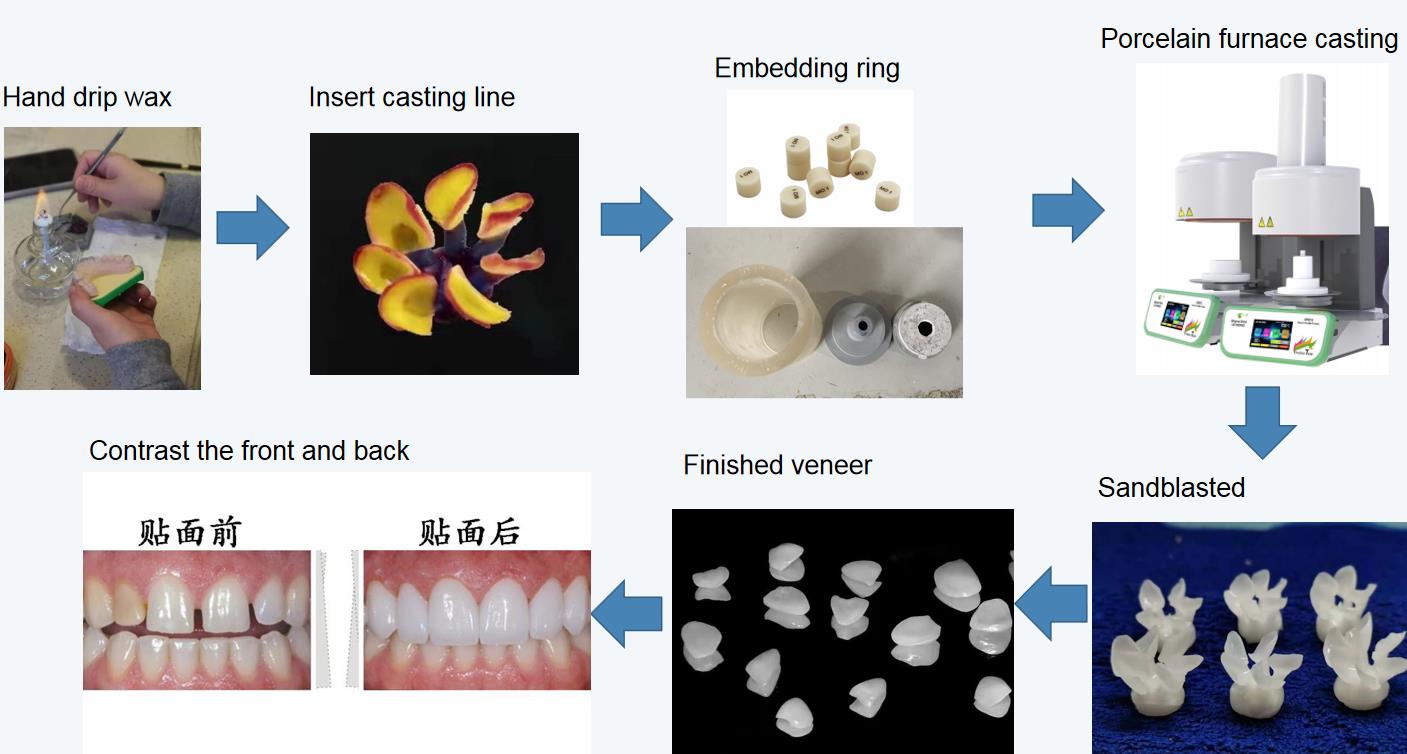

2. Aesthetic design

Traditional handmade veneer

JDM5T-G

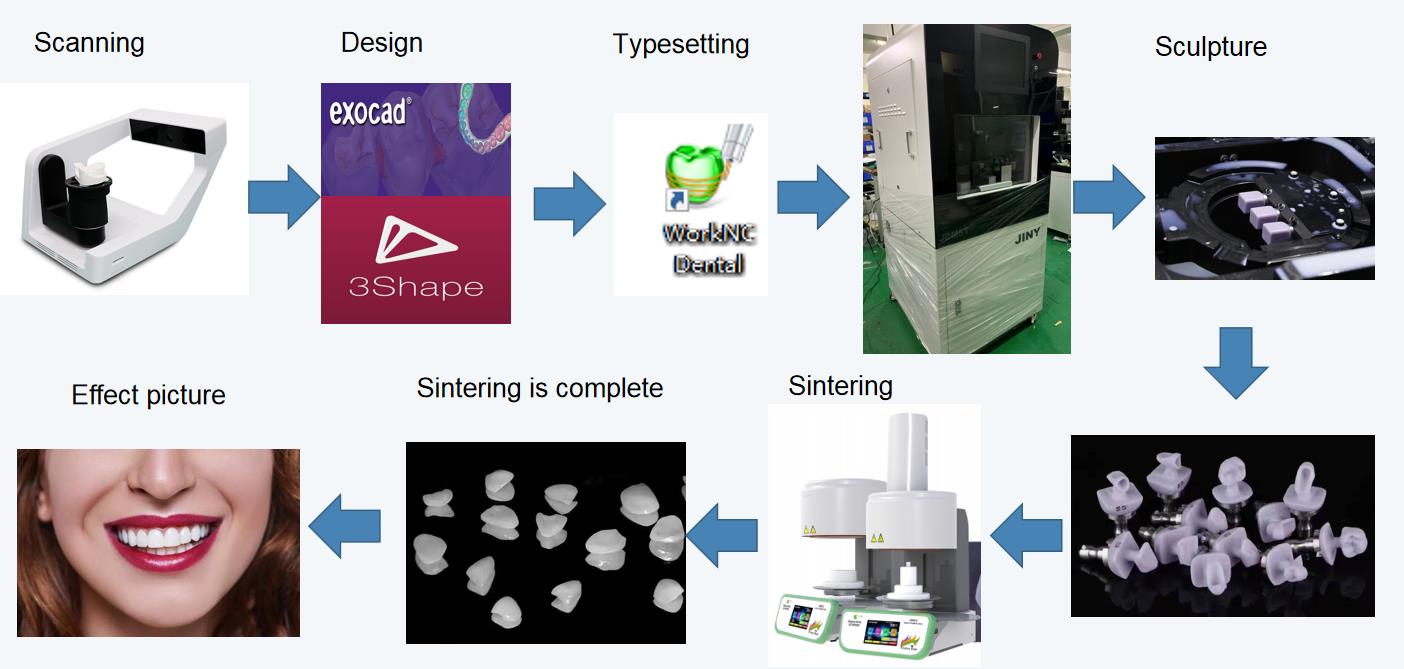

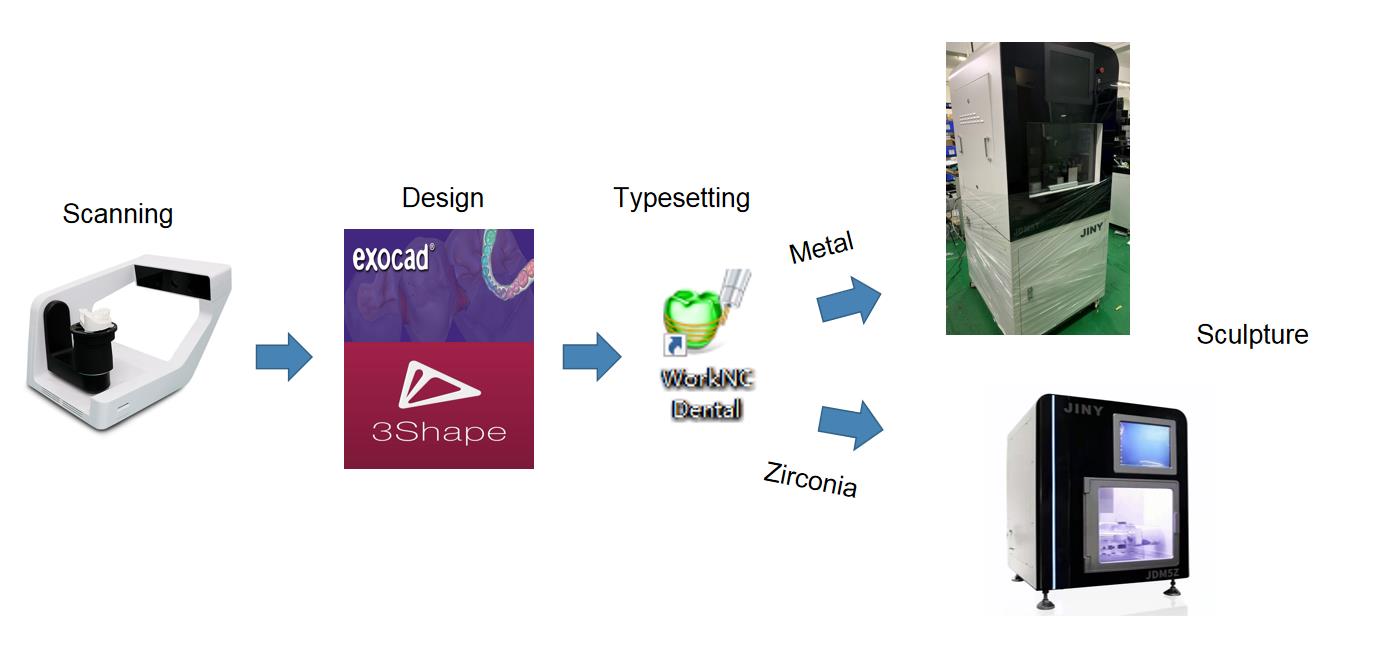

3. CAD/CAM

CAD

Materials required for zirconia

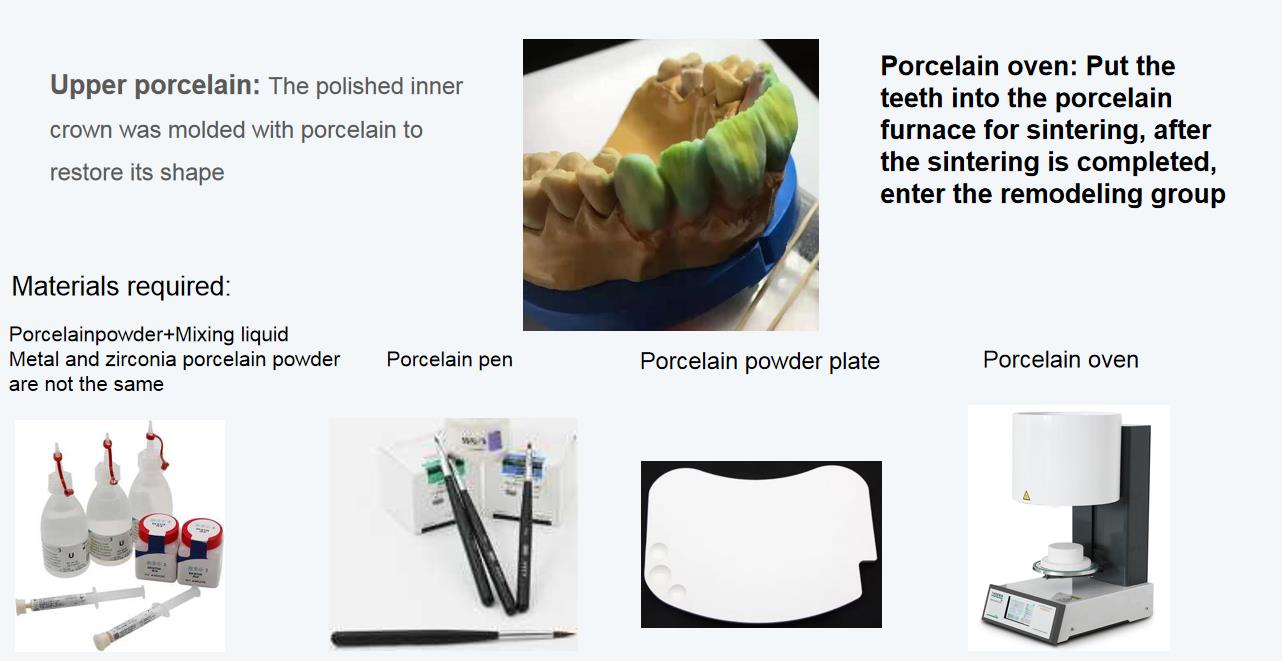

4. Upper porcelain part

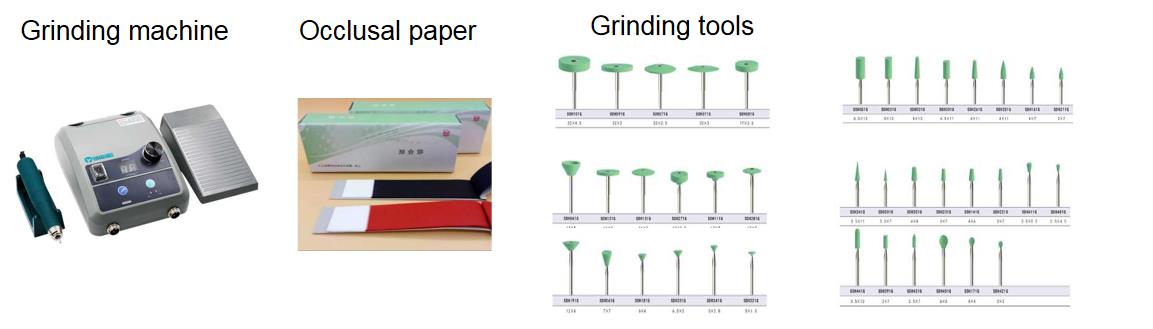

5. Car porcelain group

The car porcelain group must first ensure that there is no warping of the pontic, the adjacent relationship must be close, there is no cavity under the pontic, and good contact with the abutment, the tooth is beautiful in appearance, the development groove is clear, and the posterior teeth are tightly occluded.

Materials required:

6. Glazing group

Glazing: Glaze is to imitate a more realistic effect, with the dye can improve the chroma, make the tooth surface color strengthen or personalized dyeing.

Materials required:

7. Quality inspection department

The quality inspection department conducts factory quality inspection according to the laboratory inspection standards